Remix Truth: Toyota E-CVT Transaxle

A technology with a larger capacity battery pack, a larger power motor, a more efficient oil-electric management system, and a deep degree of interaction between the oil and electric power is called re-hybrid technology.

For at least the past 20 years, the truth of remixing, with gasoline-electric hybrids as the core technology, has all been in the hands of Toyota; will it be overstated? Today, more than 20 years later, when major manufacturers start to develop hybrid technology, no one can avoid Toyota’s patented technology in hybrid technology – ECVT electric drive axle.

Of course, the ECVT drive axle is not all patents;

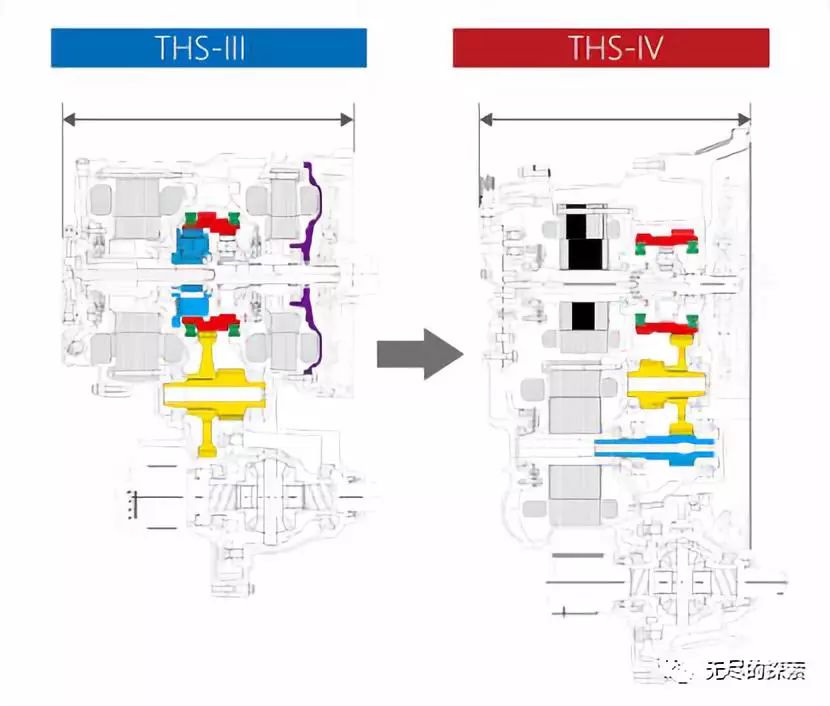

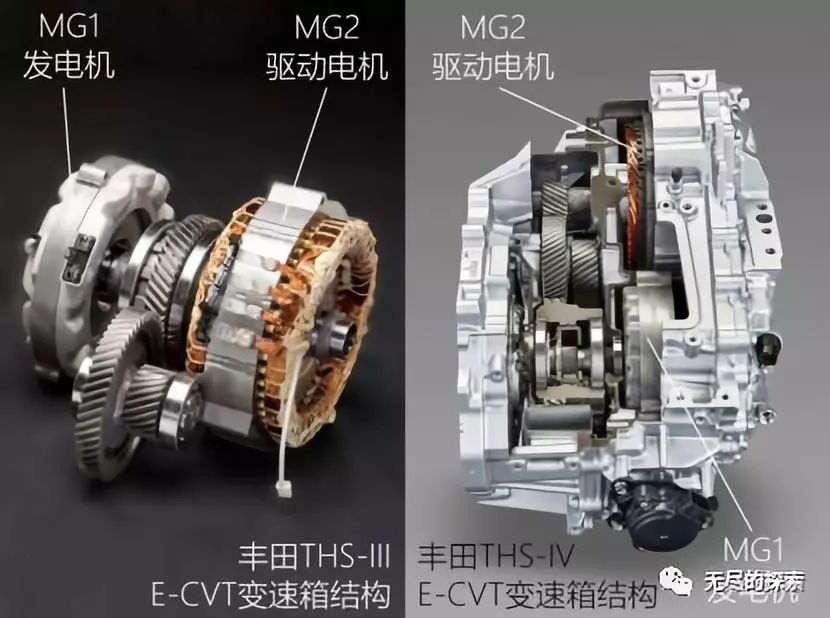

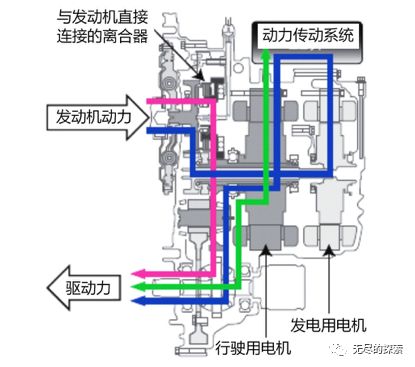

But almost all hybrid technologies have to solve the problem of torque splitting, that is, how to make the engine drive the wheels efficiently while charging the battery through the generator, and Toyota has solved this problem cleverly and efficiently through a set of planetary gears. question. At the same time, the set of planetary gears integrated inside the ECVT has truly become the core of Toyota’s hybrid patented technology.

The technical core of hybrid power is how to efficiently solve the problem of torque splitting. But before this question, OEMs need to ask themselves whether they have the ability to develop a transmission that ingeniously integrates the drive motor and generator motor in the gearbox.

Among the products that have come out so far, only a few powerful manufacturers such as Toyota, Honda, Mercedes-Benz, and BMW have solved the problem of “electric drive axle”; after that, engineers must face how to avoid the problem of Toyota’s planetary gear. patented technology.

In fact, solving the torque split is not a complicated problem, but how to arrange an efficient structure in the small internal space of the gearbox is a big problem. Because of this, the engineers who could not avoid the Toyota patent had no choice but to use the multi-disc clutch structure to achieve the torque splitting effect inside the gearbox.

Compared with the efficient structure of the planetary gear, the multi-plate clutch itself wastes a lot of force when distributing the torque, so the final effect is not so good.

Coincidentally, Honda’s understanding of hybrids completely avoids Toyota’s planetary gear patent issue. Compared with Toyota, Honda uses the same Atkinson cycle engine, drive motor/generator motor/gearbox integrated electric drive axle, but in terms of drive logic, Honda has chosen to be different, and this move has successfully avoided Toyota’s patented technology.

The reason why Japanese brands are keen to develop hybrid systems based on Atkinson engines stems from the high efficiency of such engines at economical speeds. Compared with the 25%-30% thermal efficiency of the Otto cycle internal combustion engine, the thermal efficiency of the Atkinson cycle can reach more than 40%, but this still cannot avoid the high load, high consumption and low efficiency of this type of internal combustion engine at low speed. Therefore, the blessing of the pure electric system still exists to solve these problems.

From a structural point of view, although both Honda and Toyota adopt the structure of integrating dual motors inside the gearbox, they are completely different in terms of driving logic.

Toyota’s hybrid logic can be understood as the computer constantly switching drive modes. That is, when the state of the vehicle is in the low-efficiency zone of the engine, the drive motor is responsible for driving the vehicle, and when the battery is low, the engine is started, and the battery is charged by the generator while driving the vehicle. When cruising at high speed, the engine is in a relatively economical speed range, that is, driving the vehicle to cruise at a constant speed and charging the battery.

The logic of Honda is to keep the engine charging the battery, which is somewhat similar to the working principle of the extended-range hybrid. However, Honda has limited the speed range of the engine – that is, the most efficient and economical speed range of about 2000rpm for the Atkinson cycle engine. The computer does not allow the engine speed to exceed this set speed too high.

Under normal circumstances, Honda’s hybrid technology follows that the drive motor is the first drive mode, that is, the motor is responsible for driving the vehicle in any state. When the battery power is too low, the engine starts to charge the battery through the generator, and while charging, the vehicle is still driven by the motor. At this time, a cycle pattern similar to that of a fuel cell is formed.

However, unlike the extended-range hybrid, Honda’s i-MMD system can be driven by the engine during constant-speed cruising, provided that it is within the engine’s economical and efficient speed range. This is also the biggest difference between this hybrid system and the fuel cell extended-range hybrid, and it is also the core design for Honda to avoid Toyota’s technology patents.

Plug-in hybrid: a make-up product in the cracks

As far as all kinds of hybrid models are currently on the market, Toyota’s THS-IV and Honda’s i-MMD technologies are relatively mature, reliable and highly secure traditional gasoline-electric heavy-hybrid technologies. So is the plug-in hybrid a heavy-hybrid or light-hybrid technology?

The answer is obvious, light mixing technology.

This kind of statement will definitely cause a lot of people’s displeasure. Compared with those plug-in hybrid models with a battery life of 70 to 80 kilometers on the market today, hybrid models such as Toyota/Honda with a pure electric mileage of only a few kilometers can be considered. Remix, why is plug-in hybrid not considered remix?

The reason is the concept of “the degree of mutual intervention of the oil/electric system” that we have been emphasizing before.

In plug-in hybrid technology, the degree of mutual intervention between oil and electricity is almost zero, that is, there is no interaction between the fuel system and the pure electric system. For the plug-in hybrid technology, we can boldly understand it as a XXXXXXL version of the 48V light hybrid system. Although the structure is quite different, the principle does not differ much.

Remix VS Plug-in Mix: Chassis Layout Sees Truth

The pure electric cruising range of plug-in hybrid models generally reaches 35-75km, while the cruising range of traditional heavy-duty gasoline-electric hybrids is mostly only an ugly 5-10km. The reason is simple. The battery packs of traditional gasoline-electric hybrids are relatively small, basically around 1.5-3kWh, while the battery packs of plug-in hybrid models generally have a capacity of around 7.5-15kWh. From the battery capacity, we can clearly see the gap, but at the same time a more important issue has also surfaced – the layout of the battery pack.

No one understands the reason why a large capacitor has a long battery life;

But on a car chassis where every inch of land is expensive, a battery pack that is too big is no longer good news. Obviously, hybrid is a technology that requires careful consideration. Engineers need to think about what problems hybrid technology should solve: how should the battery pack be laid out in a safe place; what structures must be sacrificed in order to get what I want?

Therefore, you will find that the battery packs of traditional remixing technologies such as Toyota and Honda are generally smaller, and the fuel tank volume is also smaller than that of the fuel version. This is because the engineers did not blindly throw the battery under the trunk, but placed it in the safest and least vulnerable position of the body, which is next to the fuel tank. And this is well thought out.

So what problem does hybrid technology solve?

Obviously, it is the energy consumption and emission issues in the low-efficiency stage of the gas turbine. Looking at it this way, many people will applaud the long battery life of the plug-in hybrid in pure electric mode. They say that the round-trip distance to work is about 50km every day! It can even be done without consuming a drop of gasoline like an electric car! It’s cool and environmentally friendly!

It’s really cool; but it’s not as environmentally friendly or as safe as you think.

Unlike Toyota’s concept of building cars based on a real hybrid platform, the 48V light hybrid models, plug-in hybrid models and domestic pure electric vehicles we see today are all “modified” based on gasoline vehicle chassis. Especially for plug-in hybrid models, it is so rude that in order to achieve a certain cruising range, a large-capacity battery pack and a high-power motor are directly installed on the fuel vehicle.

When the compact chassis can no longer lay out the battery pack, simply throw the battery pack under the trunk. While taking up a lot of trunk space, safety also becomes a problem. What’s more, just take out all the internal combustion engine power system and replace it with the motor battery, and then replace it with an electronic control system and narrower tires to make money.

The plug-in hybrid model does not make any changes or optimizations to the vehicle because it is a hybrid model, nor does it have the electric drive axle of Toyota and Honda’s traditional hybrid models, let alone solve or even consider how to split the torque into the battery charging problem. Relying solely on kinetic energy recovery and reverse charging technology can’t effectively charge such a large battery pack. Even Audi, with its e-tron halo, has not solved the charging problem for its plug-in hybrid models while driving.

The pure electric drive system is extremely demanding for the use environment. Take Beijing as an example, can you turn on the heating in winter? Can’t turn on the air conditioner in summer? High-power electrical appliances can directly discount the cruising range in half, so how much of the pure electric cruising range of about 50 kilometers is left at this time? What if you don’t have a fixed charging pile? What is it like when the plug-in hybrid is out of power?

Let me tell you, it is exactly the same as an ordinary gasoline car, but the fuel consumption of a plug-in hybrid will be greater, because you carry hundreds of kilograms of battery packs and motor systems than ordinary fuel cars.

In the final analysis, the hybrid solution solves the problem of the most fatal few kilometers in severe congestion and the problem of high consumption and high emissions in the low-efficiency stage of the internal combustion engine. It is a qualified and reliable hybrid vehicle that can be continuously self-sufficient and continuously generate electricity from the inside without completely relying on charging piles.

As for why European car manufacturers are so keen on producing plug-in hybrid models, it is because according to the difference in engine displacement, the cruising range of 25-75km can just cope with the abnormal latest European emission regulations. Furthermore, when the carbon emission of the vehicle is less than 50g/km, the car owner can receive several thousand euros of environmental subsidies, which is their original intention.