When recalling the countless American soldiers who died on the Korean battlefield, the syphilis commander MacArthur said: “At the beginning, we thought we knew everything; but later discovered that the fact is that we don’t know anything.”

This is very similar to those consumers who are waiting to buy but are full of hesitation in today’s new energy vehicle market.

Public opinion says that we are in the biggest energy crisis in the 21st century; automobile pollution is gradually destroying the homeland on which human beings live; so major OEMs have come up with various hybrid new energy technologies — even pure electric vehicles, In order to try to block the mouths of those public opinion.

With the birth of technology, a large number of series/parallel hybrids, heavy hybrids, light hybrids, range-extended hybrids and even pure electric models have come in one after another, fascinated people’s eyes and seduced your wallet like flowers. The misty news that the main engine factory will stop the internal combustion engine business in the next 5 to 10 years, a haze about new energy gradually shrouds the Chinese automobile consumer market.

The Clock of the Internal Combustion Engine: What is polluting the Earth?

The emergence of hybrid technology can indeed solve some environmental protection demands, but more and more realistic is to cope with increasingly stringent emission standards and coffee laws. As for the fact that public opinion has repeatedly emphasized that automobile exhaust has become the biggest source of air pollution in recent years, we should express our understanding. After all, if we don’t distort the facts, don’t follow the rhythm, and don’t post hot spots-these so-called experts will have nothing to eat.

The proposition of air pollution itself is very complicated: the cause of photochemical smog is pollution, solid particles are pollution, and the greenhouse effect and global warming are even more pollution. Therefore, before the direction of the pollution is not clear, it is obviously biased to blindly attribute air pollution to car exhaust, just like standing on the road and scolding the street, you must first know who to scold.

According to the data report of the World Health Organization, the largest pollution source of sulfur-nitrogen oxides that causes photochemical smog and solid particle pollution is industrial smelting pollution, accounting for 47% of this type of pollution source; while the proportion of automobile emission pollution is 29%; greenhouse In terms of effect pollution, the largest pollution source of hydrocarbons and carbon oxides is still industrial smelting emissions, while the second largest pollution source comes from animal husbandry, and the third pollution source is exhaust emissions.

There are about 50 billion livestock in the world. These livestock burp and fart every day. The gases they emit contain a lot of methane, nitrogen and carbon oxides, and these compounds are an important source of the greenhouse effect. However, the suspension or reduction of production by factories will cause serious social and economic problems, and the law cannot prohibit livestock farting, so it is only natural to curb vehicle exhaust emissions.

It is precisely because of this that increasingly stringent and excessive emission regulations and the “Coffee Rule” were born, which also gave birth to various hybrid technologies such as heavy hybrids and light hybrids. Although both are hybrid technologies, it is obvious that most people do not quite understand the differences and efficiencies between various hybrids.

Heavy Mix vs Light Mix: What’s the Difference?

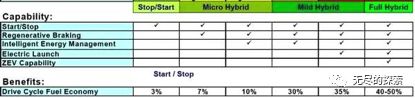

Although heavy-hybrid and light-hybrid are both hybrid technologies, they are vastly different in essence, structure, and effect. Internationally, there are actually rules to distinguish heavy hybrids from light hybrids. Generally speaking, a system with a lower degree of hybridization is called a light hybrid, while a model with a higher degree of hybridization is defined as a heavy hybrid model.

How to understand and define “mixture” is the key. The concept of mixing degree in international standards is the ratio of the sum of the power of the drive motor to the “drive motor and engine”, that is, when the engine power is rated, the smaller the power of the drive motor, the smaller the degree of mixing. When the ratio is lower than 10%, The hybrid nature is defined as a mild hybrid model. In China, the concept of hybridization is understood as the ratio of fuel consumption of hybrid power to fuel consumption of traditional fuel-fueled models. If the ratio is lower than 20%, it is defined as a light-hybrid model.

However, OEMs pay more attention to the difference in hardware when distinguishing between light hybrid and heavy hybrid. They differentiate between mild and heavy hybrids based on engine start/stop, regenerative braking, engine management, electric motor power, and hybrid effects.

Of course, the above standards will be very complicated to understand. With the rapid development of hybrid technology today, the boundaries of the above standards are becoming more and more blurred.

To give an example; in the past, the difference between light hybrids and heavy hybrids can be understood as “those that can rely on pure electric systems to maintain the vehicle’s forward motion are called heavy hybrid models, while those that cannot rely on pure electric systems to maintain driving are called hybrid models.” Mild Hybrid”. But looking at it today, this argument is no longer valid, because there are already more 48V light hybrid models that allow the vehicle to be driven by the motor for a short time when starting. Although it is only a short distance of more than 100 meters, it is enough to change the definition.

With the development of hybrid power to this day, the standard for objectively and accurately distinguishing different attributes is actually very simple, which is “the degree of mutual intervention of the two power sources”. And this sentence is also the core problem that needs to be solved and clarified in this article.

For example, Toyota’s THS technology, as a traditional remixing technology, has a very deep relationship between “oil and electricity”; the pure electric system will appear in time in the range of the lowest efficiency of the internal combustion engine, and the internal combustion engine will also When the battery is dead, charge it in time. This complementary and interdependent state is what we call “the extent to which the two dynamics intervene”.

The reason why the 48V lithium battery system and plug-in hybrid system are defined as mild hybrid systems is entirely due to the extremely low degree of mixing of “oil and electricity” between these two technologies. The role of the 48V lithium-ion light-hybrid system is more auxiliary. In most cases, it cannot become a constant and effective driving source, and the hybrid effect is extremely limited.

The degree of mutual intervention of “oil and electricity” in plug-in hybrid technology is almost zero. That is to say, when the electricity in the battery is used up, it can only be charged by an external power source. This state of being unable to effectively rely on the internal combustion engine to charge also makes the plug-in hybrid model directly bid farewell to the hybrid nature of the interdependence of oil and electricity.

48V mild-hybrid system: a life-saving medicine for high-emission engines

The 48V light-hybrid system is not a new technology–it is a relatively marginal product. The reason why it has been reintroduced by Mercedes-Benz, Audi and other brands is completely to force the life of high-emission engines.

Different from the 200V-360V high voltage of ordinary electric vehicles, the battery pack used in the 48V light hybrid system is only a constant voltage system obtained by connecting four 12V lithium batteries in series. The power density and power release are very limited, so it cannot be matched too much power motor system. Therefore, the mixing degree of the 48V mild hybrid system is extremely low.

The greatest significance of the 48V light hybrid system is to assist the vehicle to start, that is, to assist the engine when the efficiency of the internal combustion engine is the lowest and the load is the largest.

In addition, the voltage of all electrical appliances of this type of vehicle will also be changed to 48V, which allows the battery to take over more high-power electrical appliances and air-conditioning compressor systems when the engine is in a dormant (start-stop) state, maximizing Avoid the problem that the engine is forced to start charging due to excessive voltage load, so as to reduce the fuel consumption loss at idle speed, which is the so-called “electric idle speed” concept of the OEM.

The 48V light-hybrid system has an extremely low degree of mutual interference between “oil and electricity”, which also meets our above-mentioned standards for the hybrid concept. It is precisely because of this that the 48V light hybrid system is a veritable light hybrid technology.

Compared with other types of hybrid technology, although the 48V light hybrid system has very limited help in fuel saving, its advantage is that the battery and motor take up less space, but that’s all.

Of course, there are also innovative players such as Cadillac who have improved the 48V light hybrid system to a 90V system. The biggest difference from the 48V system is that the 90V battery pack and the higher-power motor system allow the vehicle to travel a longer distance in pure electric mode under certain conditions, but the larger battery pack, the larger power wheel motor, and the 90V light hybrid The nondescript nature of the system also escalates our problem to another stage: remixing.

Solving the battery problem: Toyota’s hybrid approach

Whether it is a plug-in hybrid or a pure electric vehicle, in essence, they are all developments constrained by technical bottlenecks, which is not a big mistake.

But the most principled question is whether this type of model has solved the hidden safety problem is the top priority.

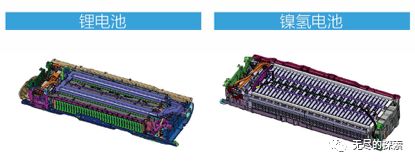

At present, batteries for hybrid vehicles and new energy vehicles on the market are mainly lithium-potassium nickel-cobalt manganate batteries, which are what we often call ternary lithium (lithium-ion) batteries; there are also manufacturers such as Toyota that still insist on Use NiMH batteries. Although it is the best move to use lithium batteries under the current technical bottleneck, it cannot avoid the fact that the characteristics of lithium batteries are unstable.

The biggest advantage of ternary lithium batteries is that they are light in size, cost-effective, and there is no current loss problem during charging, so they can be laid out in large quantities without laying too many cables. The disadvantage is that the requirements for the use environment are too high, too hot and too cold will directly affect the battery life and performance.

The ternary lithium battery cannot be overcharged or overdischarged, and cannot form a complete charge and discharge cycle. The most fatal thing is that this kind of battery is not resistant to impact. Internal short circuit, bulging or even leakage; the high temperature caused by short circuit is not a big problem, but the impact resistance has not been solved; once a leak occurs, how to extinguish it is a big problem.

Lithium-ion batteries will produce oxygen and hydrogen due to their own nature after being bulged or impacted. This is an excellent supplementary knife. Common water source fire extinguishing methods or methods of blocking air with dry powder fire extinguishers will not work on it. Because it can obtain combustion-supporting conditions from its own leaked gas, when we see a lithium battery on fire, the fire column ejected from the inside to the outside is very scary, and it is very difficult to extinguish it in a short time.

Toyota has a lot of changes in battery selection; in the North American market, it uses all lithium battery packs, in the Southeast Asian market, lithium batteries and nickel-metal hydride batteries are optional, while in the Chinese market, it only provides nickel-metal hydride battery configurations. It seems that Toyota is trying to castrate the configuration in the domestic market. Let’s not talk about whether it is to reduce the cost, but from a technical point of view, nickel-metal hydride batteries have their own advantages and disadvantages compared with lithium batteries.

Today’s nickel-metal hydride batteries can be charged and discharged at will; compared with lithium batteries, the biggest and only advantage of nickel-metal hydride batteries is stability.

The biggest disadvantage of Ni-MH batteries is how to solve the problem of overcharging after full charge. Excessive charging current after full charge is destructive to the Ni-MH battery itself, but Toyota still matches the nickel-metal hydride battery after replacing it with a higher-power motor. Hydrogen battery, which proves that the overcharging problem has been solved. Secondly, Ni-MH batteries have the problem of current loss, so when charging, one battery must be charged with one wire to solve the problem of current loss from near to far.

Therefore, in principle, nickel-metal hydride batteries are not conducive to large-area layout. After all, laying cables all over the chassis is by no means what a budget-minded manufacturer like Toyota is willing to do. In addition, under the same capacitance and energy density, the volume of NiMH batteries is larger than that of lithium batteries, which is also one of the problems that cannot be ignored.

When we realize the pros and cons of the battery system and look back at the battery layout of plug-in hybrid models and pure electric models, you will find that the battery pack of plug-in hybrid models is under the trunk, and any serious rear-end collision may The battery pack is leaking due to the impact; while the chassis of the electric vehicle is covered with battery packs in all directions, no matter which side the impact is, it may cause major problems.

And what about the traditional gasoline-electric hybrid models built on a true hybrid platform?

Obviously its engineers are very aware of the instability of the battery, so they reduced the size of the battery, kept only the capacitor size just needed, and placed it near the safest fuel tank position in the whole car. This is extremely careful thinking.

Some people may say that today’s battery management system is very mature, the temperature control of the battery and emergency power-off control can solve enough problems, and it will kill the danger in the cradle; indeed, today’s battery management technology is very mature , but obviously not enough to achieve security “mature”.

Today we can only do not create danger, but we are still far from avoiding danger; when a lithium battery leaks, our electronic control technology can prevent it from igniting an open flame, but it cannot change the chemical characteristics of the lithium battery. In other words, in addition to actively avoiding danger, the safety of the car also has the redundancy of passively accepting danger.