As a master of the latest technology, the intelligent Changan UNI-T has really come to us. Since its launch in early March, through a series of experience activities, Changan UNI-T has shown the public the concept and practice of future car functions. Changan Automobile started the establishment of the entire automotive smart ecology by breaking the routine, connecting many latest technologies and AI wisdom, and endowing smart technology with travel tools, giving it a new connotation.

Behind the visible intelligent interaction, how many invisible intelligent processes escort UNI-T’s high quality, let’s go into the factory and find out.

On April 21, the first experience officer of the First Enjoyment Program led everyone into the Changan UNI-T manufacturing base. In the form of live broadcast, the whole process was visualized, leading users to visit the intelligent production process of UNI-T, and interpreting the production behind UNI-T Stories, technical difficulties and advanced craftsmanship.

The Changan Automobile UNI-T production base has a total investment of 2.5 billion yuan, covers an area of 475,000 square meters, and has a designed production capacity of 260,000 vehicles per year. After 14.2 months of construction and development, it was officially put into operation on May 15, 2018.

Changan Automobile UNI-T production base mainly produces SUV, MPV and other models. The production line adopts advanced technology and equipment, and its automation rate reaches more than 80%.

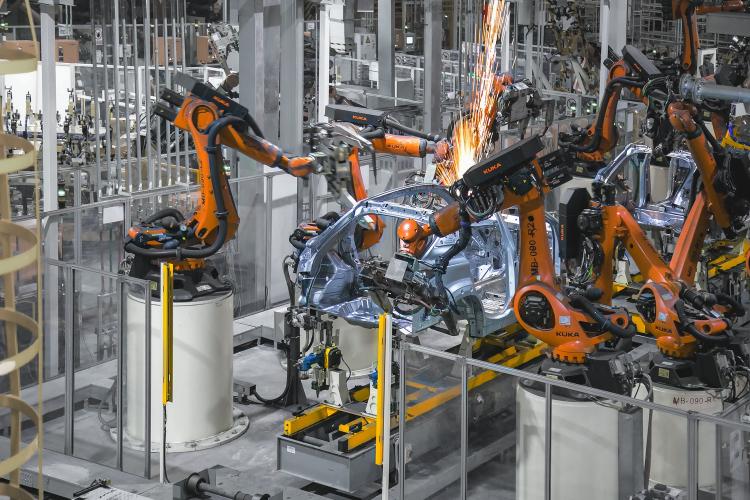

The live broadcast fully demonstrated the stamping workshop, welding workshop and assembly workshop of the Changan UNI-T manufacturing base.

Among them, the stamping workshop is a fully enclosed high-speed double-arm mechanical production line, with a production cycle of 15 times per minute, low noise and environmental protection, and adopts key technologies such as synchronous control, numerical control hydraulic cushion, and fully automatic mold change. The welding workshop adopts 4-model flexible line for the first time, and the automation rate reaches 50%. The painting workshop is a water-based 3C1B+VOC terminal incineration process, using bottom extrusion, bottom sealing, and spraying robots. The general assembly workshop adopts a large liftable slide plate, intelligently adapts to the working height, automatically assembles the AGV on the chassis, automatically squeezes the glass, and torque control system.

The stamping workshop has a total construction area of 25,820㎡. There are two 2400T double-arm fully automatic high-speed closed stamping production lines. The maximum production cycle is 15 (punching times) per minute, and the annual maximum production capacity of the workshop is 7 million (punching times), representing today’s international The most advanced production level of large-scale complete stamping equipment. Using key technologies such as synchronous control, fully automatic mold change, energy-saving CNC stretching pads, and full digital monitoring, it is mainly responsible for the stamping production of large-scale outer panels of Changan Automobile models.

The welding workshop covers a total area of 42,000 square meters, mainly composed of a flexible main line, a rigid main line and body storage and transportation lines. The design production capacity is 260,000 vehicles/year, and the maximum production capacity is 390,000 vehicles/year. The workshop configuration is international first-class There are 336 sets of high-quality fully automated equipment.

The assembly workshop of Changan Automobile UNI-T production base is the largest workshop of Changan Automobile. It is composed of rain lines, with a designed production capacity of 260,000 vehicles per year and a maximum production capacity of 390,000 vehicles per year. The workshop is equipped with 149 sets of fully intelligent and automated equipment with international first-class quality, accounting for 80%, to realize the intelligent monitoring and management of production, equipment, quality and logistics mutual decision-making. Increase production efficiency by more than 15%, increase resource utilization by more than 10%, shorten product development cycle by more than 25%, reduce operating costs by more than 15%, reduce defective product rate by more than 25%, and achieve 100% operation monitoring rate of key manufacturing equipment. The intelligentization of workshop manufacturing is at the leading level in the same industry.

It is reported that the first mass production of Changan UNI-T will be delivered to “first-time experience” users in May, and it is planned to be officially launched in June.

review:

On March 5, Changan Automobile’s new serial SUV model UNI-T was officially released

On March 10, Changan UNI-T completed China’s first L3 autonomous driving mass production experience

On March 31, Changan UNI-T innovatively launched the first pick-up mode for unlisted cars

On April 10, Changan UNI-T all-round intelligent technology experience