Today we are going to talk about the third part of the chassis drive system – the universal transmission. This article mainly introduces the four contents of the universal transmission: installation position, function, structure, and failure (the universal transmission part).

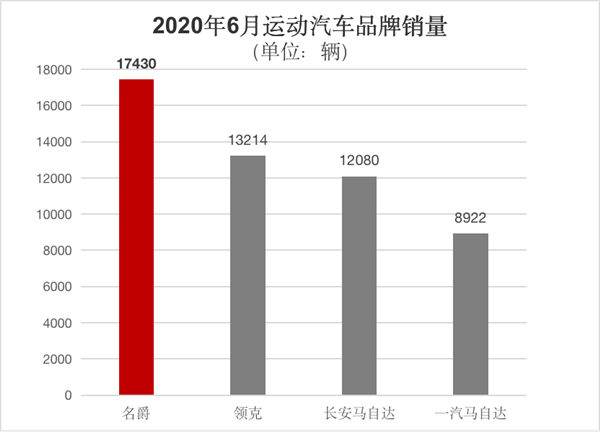

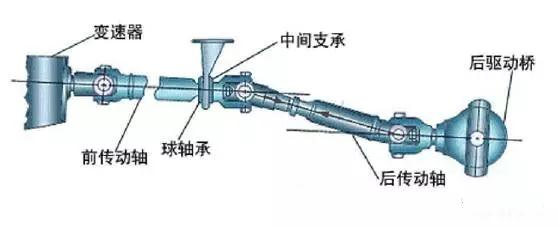

Installation position: between the transmission and the drive axle

Function: The universal transmission device is a device for transmitting power. Its function is to connect the output shaft of the transmission and the input shaft of the main reducer that are not on the same straight line, and ensure that the angle and distance between the two shafts are constantly changing. Power can be transmitted reliably.

Structure: The universal transmission device generally consists of a universal joint, a transmission shaft and an intermediate support.

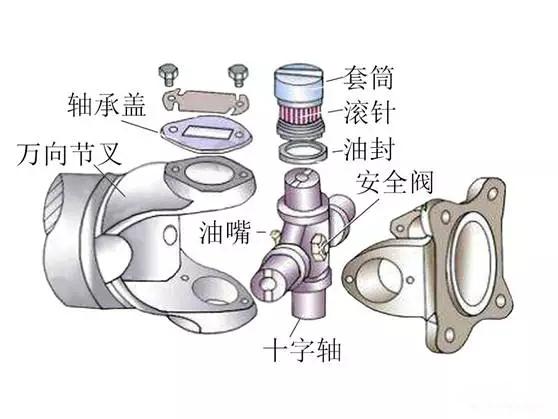

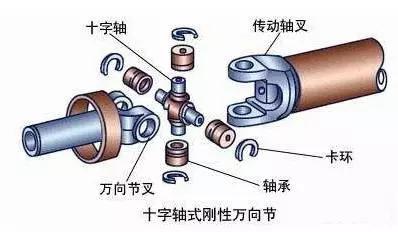

Universal joints: Universal joints are mainly composed of universal joint forks, cross shafts and bearing sleeves, and some also have grease fittings

In some cars, the bearing is not locked by the bearing cover, but by the snap ring.

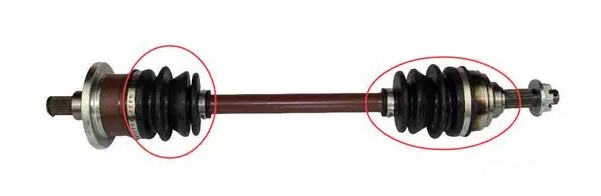

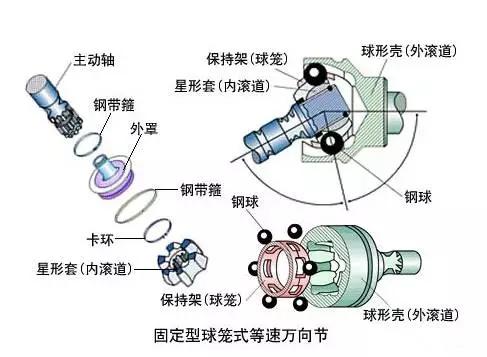

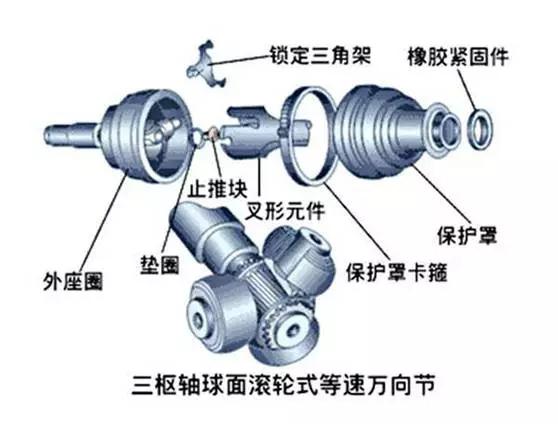

There is also a universal joint on the half shaft of the front front drive engine (the red framed part in the figure below)

It is roughly divided into two types: cage type and three-axis type. The structure is as follows:

transmission shaft

It should be noted here that the universal joint forks at both ends must be on the same plane when the transmission shaft is installed. That’s because although the working characteristics of the ordinary cross-shaft universal joint can adapt to the change of the angle between the two axes of the driving and the slave, but this kind of universal joint has the characteristic of non-uniform velocity, that is, when the driving shaft rotates at a uniform speed, the speed of the driven shaft It changes periodically from time to time. This unequal speed will cause impact on the driven axle gear. The impact not only makes noise, but also accelerates the damage of the driven axle gear.

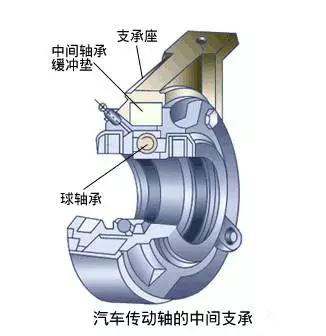

Intermediate support

The intermediate support is composed of rubber elastic elements, bearings and so on. Because the honeycomb-shaped rubber pad is elastic, it can meet the compensation for installation errors and displacement caused by engine movement and frame deformation during driving.

Malfunction (cardan transmission part)

The common faults of the universal joint transmission are abnormal noise and vibration caused by the increase of the swimming angle.

Rear drive:

1. Universal joints and expansion joints

Phenomenon: When the car starts or the speed changes suddenly, the transmission device makes a “clang” sound; when the car slows down, the transmission device makes a “crack, croak” sound.

reason:

A. The universal joint bearing is loose due to wear or impact;

B. The spline of the expansion joint of the transmission shaft is loose due to wear or impact;

C. The connecting bolts of the flange of the universal joint are loose.

2. Drive shaft ringing

Phenomenon: When the universal joints and expansion joints are in good technical condition, the transmission shaft makes periodic noises when the car is running; the faster the speed, the louder the noise, and in severe cases, the body chatters, and even the hand holding the steering wheel is paralyzed sense.

reason:

A. The drive shaft is bent or the shaft tube is sunken;

B. The transmission shaft tube and the universal joint fork are not aligned or the transmission shaft is not dynamically balanced;

C. The balance piece on the transmission shaft is lost;

D. The expansion joint is not installed according to the mark, which makes the drive shaft unbalanced, and may cause the forks at both ends of the drive shaft to be out of the same plane;

E. The fixing bolts of the intermediate support hanger or the connecting bolts of the flange of the universal joint are loose, which makes the position of the transmission shaft deflected;

F. Improper fastening method of the rubber-clamped intermediate support causes the front end of the intermediate drive shaft to deviate from the original axis.

3. Middle support ring

Phenomenon: When the car is running, there is a continuous “beep, beep” sound, and the faster the speed, the louder the sound.

reason:

A. Rolling bearing delamination, pitting, excessive wear or lack of oil;

B. The installation method of the intermediate support is improper, causing the rolling bearing to bear additional load;

C. The rubber ring is damaged;

D. The frame is deformed.

Front drive:

1. Vibration during driving

Phenomenon: The vehicle body shakes during driving.

Cause: Deformation of the half shaft.

2. Abnormal sound when turning the direction

Phenomenon: There is a “click” and “click” sound when turning the direction, especially when walking in the general direction.

Reason: Generally, it is caused by the wear and tear of the half shaft ball cage and lack of oil.

3. Abnormal noise during driving

Phenomenon: There is an abnormal sound at the half shaft during driving.

Reason: It mostly occurs in the inner ball cage, which is caused by dry oil in the ball cage.

Source of pictures and texts: Auto Repair Collection.