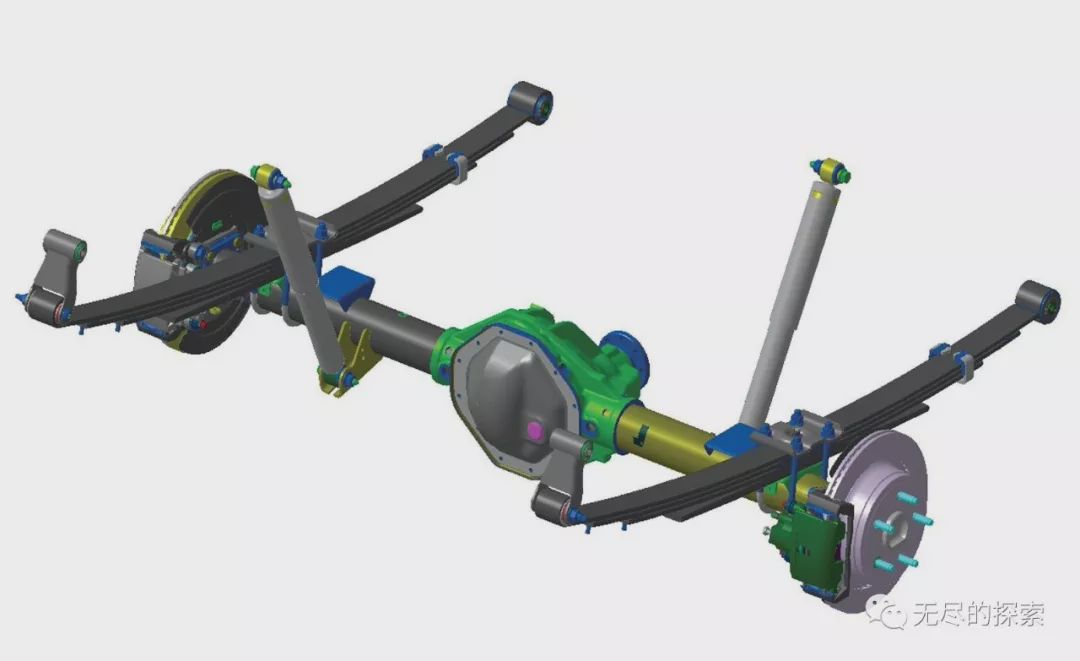

Steel plate suspension is the oldest and oldest suspension structure. It has been widely used in carriages before the birth of automobiles; after the birth of automobiles, many structural features of automobiles have also evolved from carriages. In the design of cars or off-road vehicles, trucks and even some armored vehicles and tanks, steel plate suspension is almost the only suspension method; and steel plate suspension, as a very practical, reliable and economical product, has been multiplying and changing, and it is still used in automobiles today. used in many fields of manufacturing.

Many of the models we commonly use for off-roading are still steel plate suspension structures, especially in pickup trucks, most of the rear suspensions are of this type, whether it is Ford, Toyota, Isuzu, Nissan or other domestic brands. , so when it comes to “playing with cars”, the modification of the steel plate suspension is an inevitable topic.

Characteristics of steel plate suspension:

Compared with the suspension methods of other structures—whether double-wishbone type, multi-link type, McPherson type, or trailing arm type, the steel plate suspension has their incomparable advantages, because it is the only one It is the first suspension method that can play the role of elastic support and fixed axle position at the same time; in other suspension structures, no matter which one is the function of elastic support elements and fixed axle elements respectively; including the most widely used The unique multi-link + spring (air) suspension method.

Another obvious advantage of steel plate suspension is that it occupies a very small space, which is unmatched by any suspension method; on models with steel plate suspension, the position of the spare tire and the position of the fuel tank are very easy to arrange, and It does not affect the interior space of the car, while other types of suspensions cannot do it at all; or even if it is barely achieved, the performance of the suspension-especially the performance of the large stroke will be very different.

Among all the suspension methods, there is an extreme exception that can also achieve the characteristics of the steel plate suspension, that is the torsion bar (lateral) suspension commonly used on tanks; it can have the same positioning and elastic support as the steel plate However, the biggest problem with the torsion bar suspension is that it will greatly change the wheelbase of the vehicle when it releases and compresses the stroke. If this structure uses steering wheels, it will cause poor steering characteristics and sensitivity. The rules change, so it’s rarely used on modern-designed vehicles, except for a few exceptions (such as North American baja series cars).

At the beginning, the application of steel plate suspension in automobiles was the front and rear suspensions; this includes many applications, including front axle horizontal balance, front and rear longitudinal, rear multi-axle balance, etc.; those who are now cowhide The coquettish ultra-luxury brands were all this “carriage configuration”, B Bugatti, RR Rolls-Royce, M Zeppelin, etc.; but with the invention-creation-application of other suspension methods, The problems of steel plate suspension in terms of comfort and handling are gradually exposed, so it is not used much in modern cars, but it is still the best choice in many fields that emphasize reliability, durability, and economy, so it is used in many Still available on trucks, pickups, and hardcore off-road vehicles.

It should be noted that steel plate suspension is not necessarily synonymous with bumps; it can actually achieve high performance. For example, Ford’s Mustang Mustang sports car has insisted on using hard bridge + steel plate suspension for many years, and many baja series The racing car in the race also uses steel plate suspension; so it is not that the performance of the steel plate suspension is not good, but that you have not selected the right product, and the ability of the right steel plate is not inferior to other types, just like many people say that McPherson The type of suspension is not strong, but the fact is that this “weak McPherson” has been applied to military armored vehicles. The Movag armored vehicle series equipped by the US Marine Corps is this suspension method. So it’s not that the MacPherson suspension is weak – it’s that the material used to make it isn’t strong enough.

There is still a big problem with the steel plate suspension because it has always been the main suspension structure of commercial vehicles, and now even high-configuration commercial vehicles have air suspensions, and most of the steel plates are low-end and low-end vehicles. In the eyes of many people, it is “not advanced enough”, which is an important reason why many manufacturers avoid using it. In addition, in small cars and light cars, the smaller and lighter the car body, the more difficult it is to take advantage of the steel plate suspension, because The characteristics of the steel plate suspension are indeed less sensitive than the lightweight multi-link or McPherson—and these are exactly the opposite of the “comfort and handling” emphasized by the manufacturer, so the steel plate suspension It is inevitable that the frame will be left out.

Modification method of steel plate suspension:

Whole frame replacement and replacement of lifting lugs

The modification of the steel plate suspension we are talking about here mainly refers to pickup trucks and hard-core off-road vehicles; their modification purposes or reasons are nothing more than two, one is to increase the load capacity, the other is to improve the passing capacity, or both; therefore Their modification methods are mainly to replace the entire steel plate, add a better elastic steel plate as the main support, or replace the extended lifting lug.

Replacing the entire steel plate is actually very simple, because the steel plate itself is not a high-tech product, so generally speaking, production is not difficult. The difficulty is to obtain the corresponding data, which is a cumbersome and troublesome thing that requires a lot of work and a long time According to the manufacturer’s standard, this cycle is generally 18 months or more, so don’t think that things that look simple are also easy to do. It should be noted that many so-called heavy-duty steel plates on the market, whether domestic or imported, have the problem of fast attenuation in many cases. This should be paid enough attention, otherwise the meaning of replacing the steel plate will be meaningless.

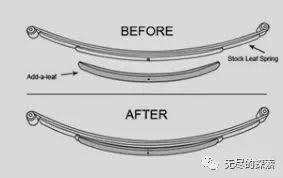

Another key point of steel plate suspension modification: raising

In addition to replacing the steel plate of the entire rack, the increase can also be solved by adding a certain steel plate with a greater load capacity. The advantage of this method is first of all that it is more economical. Replacing a piece of steel plate usually does not make the vehicle more bumpy, but just like replacing the whole steel plate, more attention should be paid to the selection of products; because relying on a single steel plate to solve the load, elasticity The difficulty with comfort will be higher than that of the whole steel plate.

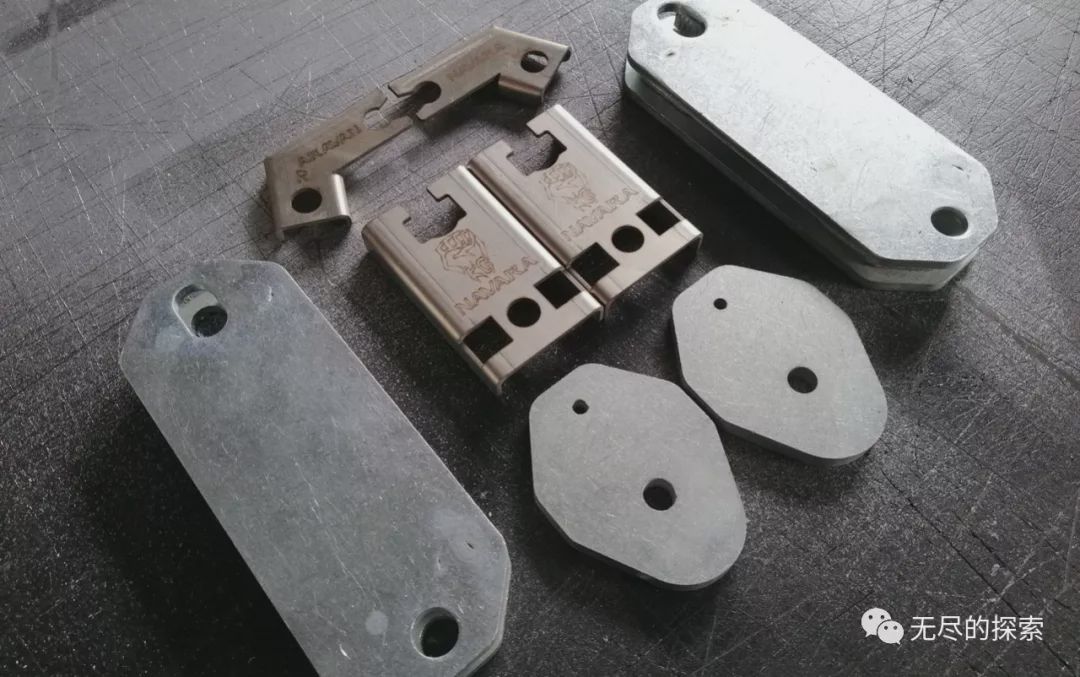

Replacing the lifting lug is also a very common method. The advantages of replacing lifting lugs are obvious; the lifting lugs are simple, cheap, easy to disassemble, mature technology, free lifting data, etc.; so it is widely used. In recent years, the products that use lifting lugs have increased. The product of folding lugs is added, which further increases the richness and performance of the modified lifting lugs.

The difference between lug types:

Extended Lugs and Folding Lugs

Ordinary extended lugs:

In fact, it is to extend the height of the connecting seat of the steel plate, which is equivalent to raising the vehicle, and it will also change the input angle of the transmission shaft; the length of the raised lifting lug can be purchased according to your own needs, and the lengthened lifting lug is generally used It should not be raised more than 2 inches, because if the length of the lifting lug is too high, it will easily cause many problems, mainly in the following aspects;

-

The problem of vehicle stability after lengthening; after lengthening the lifting lug, since the length of the lifting lug is increased as the swing arm of the steel plate, the rear fixing position of the steel plate will move down, which is easy to form lateral swing compared with the original lifting lug, which will further cause the vehicle The stability of the suspension is affected, and it will be more obvious when passing a bumpy road section quickly. This is because the lifting lug itself has to bear the force of longitudinal distortion when the steel plate suspension is moving. The shock absorbers make it harder to control body attitude.

-

After the lengthening, the strength of the lifting lug itself will also be strengthened because of the lengthening of the swing arm; the wear resistance and durability will also be processed simultaneously;

-

Because of the lengthening of the swing arm of the lifting lug, the displacement of the axle during the moving stroke increases, which will also affect the driving stability and safety of the vehicle. The influence of stability mainly comes from two aspects; one is that the elevated center of gravity affects stability; the other is the increased displacement of the axle caused by the relative compression of long lifting lugs and steel plates, both of which are magnified variables and must be It will affect the driving stability of the vehicle.

Folding extended lugs:

Advantages of folding lugs: This lug was originally designed for use on rock climbing bikes

-

In the normal working state, its folding structure is in a “stacked” state. In this state, the relative distance between the two connection points is short, which has obvious stability advantages over the single extended lug;

-

When the lifting lugs are unfolded, the suspension stroke can be greatly increased, especially when the lifting lugs are opened, the impact on the downstroke is greater, which is of great benefit for rock climbing and rainforest crossing;

The downstroke of the folding lug is too large, causing the shock absorber to pull the axle at the end of its stroke, so a limit belt is needed to ensure that the shock absorber is not pulled.

Disadvantages of folding lugs:

-

Excessive strokes are often greater than the downstroke of the shock absorber, and long-term large-stroke movements will cause obvious tensile impact burden on the shock absorber, so it is necessary to increase the limit belt to limit the bottom dead center.

-

Even if the shock absorber has a downstroke limit design, we recommend using a limit belt to limit the stretching action of the downstroke; this is because when the off-road vehicle involves the amplification of the downstroke, it must be the environment When the harsh working conditions are complicated, then in this situation it is likely that the logistics service is not sufficient and timely. In this case, we cannot ignore the limit working pressure of the shock absorber, but we must consider the shock absorber. The serious consequences of the damage, so I highly recommend doing the limit treatment of the downstroke.

After lifting, the limit block of the upper stroke must be extended downward.

-

Another one is that the large stroke brought by folding lugs is of great benefit in off-road or even extreme activities, but it is also necessary to evaluate the driving stability of the vehicle on bumpy roads. If the excessive stroke affects the high-speed stability It is necessary to consider adopting some control methods to ensure the safety of the vehicle. There are many means available, such as adding a balance bar, controlling the setting of the brake stroke, etc., all of which can achieve the purpose of driving safety.

Regardless of the lifting method, one thing to remember is that when the vehicle is raised, the top dead center of the vehicle’s travel will change, and the original upper limit rubber pier itself will be useless. It must be extended downward, otherwise The steel plate suspension itself will fatigue and even break prematurely because there is no upper limit. If the first positioning steel plate is broken, the vehicle will be very dangerous in driving. If it is a long-distance crossing, then it will cause problems. It will be more serious, so remember that modification is not as simple as it seems. It involves all aspects of the problem, and you must consider it carefully before doing it. (Some of the pictures in this article are taken from the Internet, if there is something wrong, please delete it)

“It’s been 160 years since Darwin published his theory of evolution in 1859; we believed in evolution, and Darwin became a theist — he believed in God. ”