First of all, I would like to thank Brother Laobai in Xuzhou and Mr. Li for their great help. Although I did not buy a chassis or an announcement when I went to Xuzhou, I learned a lot of knowledge from Brother Laobai. Everyone has the opportunity to learn and communicate with Brother Laobai. After posting this post, many people must have sprayed my aluminum profile frame and felt that it was not strong.

In fact, I can say that the sub-beams brought by general RV factories are not as strong and have so many beams like the ones made by the old white brother. Many factories have five beams, which are generally 4cm square tubes, and the weight of one person will deform the beams.

But I made it with aluminum profiles, and tested that one person can only press one beam, and it can’t be deformed. For aluminum, do not use aluminum square tubes, but use aluminum profiles, which have a reasonable structure and can be used for load bearing. The previous car mention post has already been posted, so I won’t say much here. People who have followed me before should also know that my idea is the whole car with an aluminum profile skeleton and a skin on the surface.

I originally planned to make an announcement by myself, but it was too expensive, so I could only buy ready-made ones, so the shell I mentioned did not have insulation and a skeleton, it was a pure layer of fiberglass skin. I used to plan to use aluminum for the skin, but later I chose fiberglass. One is that fiberglass has a better thermal insulation effect. Second, the exterior of the bulletin is now shaped, and it is made of aluminum, which basically cannot achieve that effect. But it does not mean that the use of FRP is stronger than the aluminum skin. The single-layer FRP has good elasticity and is easy to deform.

Sandwich structure, let’s not say much, I didn’t plan to change the C-type so early, but later many people on the forum sprayed my post on the sandwich structure, so I wanted to make a skeleton structure for them to see, it’s based on the facts Face, although the cost is not low, but I am happy.

As for the venue, it’s downstairs in my house, it’s cool in the afternoon, there’s a shadow from the building, the wind is strong, it’s cool, and the electricity is cheap (actually, the power consumption of a car modification does not exceed ten degrees), the most important thing is to tell everyone that modification is not No matter how difficult it is, you can do it downstairs at home, don’t regard modification as such a lofty thing.

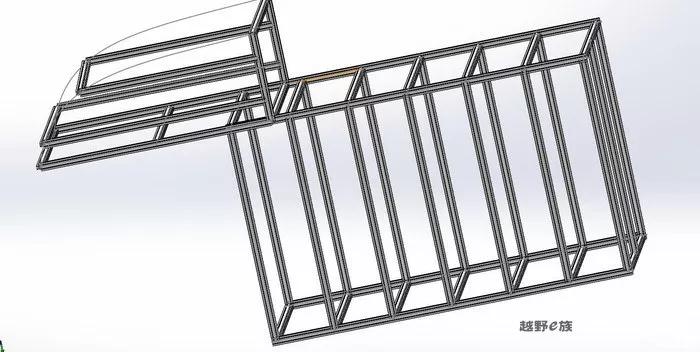

This is the aluminum profile frame I designed, which is just a sketch, without any horizontal connection or oblique connection. The glass fiber reinforced plastic shell can be regarded as covering the frame, and it is fixed on the frame with Sika glue. The function is heat preservation. When a collision occurs, the FRP can also withstand a certain force. You want to ask, can this glue work? The answer is that the sandwich structure is also used to glue the three-layer structure together. My design can only be stronger.

This is the frame and heat preservation from the original factory. If the requirements are not high, this is actually enough. The advantage is that it saves trouble, but the disadvantage is that I think the skeleton is not thick enough, and there is no connection between the left, right, up and down. And some refitting factories in the south like to use wooden skeletons, not for saving money, because the cost is similar, maybe for weight reduction, I don’t know if it is. . The skeleton has nothing to do with the FRP factory, it mainly depends on the needs of the refitting factory. After all, the skeleton is not expensive, and the steel pipe is only a few dollars.

This is the fiberglass skin I mentioned. There is only one layer of skin, and the thickness is about 2.5mm. Because it is very soft, I used a wooden frame to reinforce it and drive it home.

The roof of Wolfson’s car is very thin, and it was deformed and dented after a few steps. But the new generation Transit is much harder.

In this picture, you can see the fixing method of the manufacturer. The steel corner fittings are first fixed on the FRP skin, and then fixed on the sub-beam with screws. As for the wood board, it should not be a wood board, but a double-sided FRP bottom plate given by the manufacturer, but this bottom plate delays things, so I don’t want The bottom plate, this height will be replaced by wooden boards, we will look at the later modification.

First, use aluminum profiles to build a shelf, and top up the glass fiber reinforced plastic shell. The next step is to remove the wooden frame and steel sub-beams that were brought out of the factory, and replace them with all-aluminum profile sub-beams and frames. Because the typhoon has not passed, it cannot be dismantled yet, and the next step is to wait for the typhoon to pass.

The thickness of the FRP on the four pillars around the FRP should be thicker, it should be 5mm, it is very hard, and the support should be okay, but I changed the frame to be mainly made of aluminum profiles for load-bearing.

The Bosch horse saw arrived, and it is very easy to cut the sub-beam. At first, the seller recommended that I buy a 1300-watt one, saying that it is more useful. But I finally bought a 1200-watt one, which was hundreds of dollars cheaper. With a difference of one hundred watts, how much better can it be used? It feels like fooling me.

Remove the fixed angle iron that comes with the factory.

Cut the sub-beam and prepare to replace the all-aluminum profile sub-beam. The picture of the aluminum profile sub-beam will be uploaded tomorrow.

I was afraid of strong winds at night, so I didn’t rush to cut the rear part. I will continue to cut it tomorrow and replace it with an all-aluminum sub-beam. As for the aluminum sub-beam, I checked, and the hardness is not bad. The same volume of aluminum is not as hard as steel, so it is necessary to increase the volume of aluminum profiles. If aluminum and steel are of the same quality, I think the hardness of aluminum should be better.

The auxiliary beam provided by the FRP factory has been removed.

Clean it up and prepare to install the all-aluminum profile subframe. However, it was later discovered that the size of the fixing screw was wrong, and I needed to buy it again, and I had to wait for a few days. The original steel sub-beam is five beams. With aluminum profiles, I’m planning to use 8-9 beams.

In terms of weight comparison, the steel sub-beam should be less than 100kg. Aluminum sub-beams, one beam is 2.2 meters, and the weight is 3.7 meters, so one is more than 8kg, and if there are nine, it is more than 73kg, plus vertical links, the overall weight is not much different. However, after the aluminum profile sub-beam is used, it will not rust, and the supporting area is larger. The surface area of the original steel sub-beam is 2.2 meters * 0.04 meters * 5 pieces, and the total area is 0.44 square meters. With aluminum profiles, the surface area is 2.2 * 0.06 *9 roots, which is 1.188 square.

In other words, the pressure that a single aluminum profile needs to withstand is theoretically only one-third of the original steel sub-beam, the theoretical value. Even though aluminum itself is not as strong as steel, it is stronger because it bears less load.

The typhoon has passed, the weather is hot, and I only work in the afternoon. Apply Sica glue between the rubber and the girder. The advantage is that there will be no water between the girder and the rubber. I don’t know the disadvantages, but there should be no harm. . . The glue is not thick, it is just a sealing effect. I saw a truck that was less than ten years old, and the edge of the steel pipe of the sub-frame had rusted through, so I planned to use aluminum for the sub-frame from the beginning, so it can be said that it will never rust.

Between the sub-beam and the main beam, use m10 screws to fix, the number is about 20 or more.

I tried the load-bearing today, a single 2.2-meter beam, my father and I sat on both ends, the total weight is 170kg, there is no obvious deformation, it is stronger than the original 4cm thick steel pipe, and I will post more pictures tomorrow.

There are a total of eight horizontal sub-beams in front and back, and the vertical ones are tomorrow. All screws fixed, no welding. In terms of strength, there is no problem. They are all fixed by m10 screws. The car itself is fixed by screws in many places, so don’t worry about it. To be honest, this sub-beam is much stronger than the original steel sub-beam brought by the FRP factory, and the weight of the sub-beam will be updated after finishing.