At the Frankfurt International Motor Show and Tokyo International Motor Show held in the second half of this year, we have clearly seen a clear development direction of new energy power from the two major automobile industry systems in the East and the West. And this kind of transformation towards the new energy era is not only limited to the interior of automobile manufacturers, but also depends on the transformation and upgrading of the entire parts industry.

In other words, before we see the comprehensive new energy transformation of automobile manufacturers, parts companies have actually completed a round of transformation and upgrading of new energy. At this year’s Shanghai International Auto Show, Dana’s high-profile participation in the exhibition, as well as the new energy electric drive technology released at the Shanghai International Auto Show, can illustrate the problem.

Unlike other parts companies that focus on a certain field, Dana’s reputation in the market is obviously much greater. In most cases, Dana’s axles are passed on to users as a major selling point of the model. For example, the DANA axle of the Jeep Wrangler is a prerequisite for its off-road performance to be guaranteed.

Like those old manufacturing brands, the history of Dana also originated from the manufacturing explosion in the early 20th century. In 1904, engineer Clarence W. Spicer started the manufacture of universal joints in New Jersey, China. Since 1919, Dana has successively completed the acquisition of frame, gearbox and transmission shaft manufacturers, and gradually formed a complete corporate structure of the transmission industry. Drive axle technology also became the most important business unit of Dana at this time. From this point of view, Dana has been developing in the field of drive axles for a full century.

Thanks to Dana’s continuous progress in the field of transmission, after a century of development, Dana has become the world’s top manufacturer of transmission system components. As the main business, Dana has also invested a lot of experience in the progress of the transmission system to further optimize the mechanical transmission mechanism. In the late 1960s, Dana officially entered into the research of hybrid power system, and made advance planning at the level of power coupling between electric motor and engine.

From this perspective, Dana’s road to electrification should have originated in the late 1960s.

However, the real breakthrough point for Dana in the new energy field is the arrival of the new energy era. Since entering the second decade of the 21st century, the new energy power industry has begun to develop on a large scale. As one of the core technologies, the power battery industry has become the focus of everyone’s attention. In this round of new energy and electrification, Dana has given full play to its advantages in the field of transmission and started to develop electric drive technology.

From the perspective of the vehicle’s power architecture, the main power components of new energy vehicles include electric motors, batteries, and power management systems, commonly known as the three-electric system. And the corresponding transmission system – due to the change of driving power, the transmission system of new energy vehicles is also slightly different from that of traditional internal combustion engine vehicles.

Therefore, in the field of electric drive, Dana took the lead in launching an electric gearbox based on the traditional mechanical structure. In order to deal with the gearbox that the electric motor cancels compared to the engine, and thanks to Dana’s accumulated experience in the design and development of precise and efficient transmission systems in the traditional transmission field, this set of electric gearboxes also retains Dana’s High-precision tradition and high-efficiency performance.

At this time, Dana has entered the new energy industry as a secondary component supplier. However, what Dana has to do is far more than that simple.

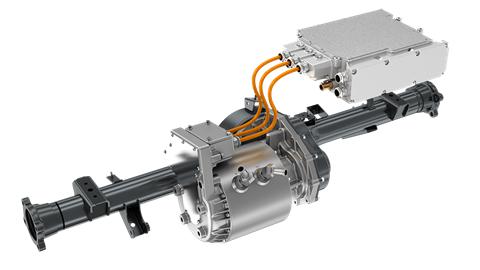

In the second half of 2018, Dana established a joint venture partnership with Hydro-Quebec. According to the agreement, Dana became the largest shareholder of TM4 under Hydro-Québec. And Dana also logically obtained TM4’s electric motor, generator, power electronic equipment and control system technology. At the Shanghai International Auto Show in April this year, Dana integrated the core technologies of TM4’s permanent magnet motor, thermal management system, coil winding, motor and inverter control algorithm into Dana’s electric drive axle, and launched the TM4 MOTIVETM motor and inverter. As a result, Dana’s position in the new energy power industry has risen from the level of a secondary component supplier to a supplier that can provide a complete set of new energy electric drive solutions for OEMs.

From a structural point of view, the TM4 MOTIVETM motor and inverter have high space compatibility, which makes this system more layout-friendly for small cars. In terms of size, the integrated Dana inverter is 33% smaller than the previous generation of products. The weight of the whole set is 50 kg. It can be expanded to a maximum rated power output of 150 kW and 11,000 rpm score level.

For the current mainstream passenger cars, the combination of this electric drive system, whether it is a hybrid or a pure electric drive, the output level of such an electric drive axle can already meet the needs of the market.

It is reported that the new energy electric drive axle system composed of TM4 MOTIVETM motor and inverter can independently provide new energy solutions for small passenger cars with a front-wheel drive platform with a transverse engine, and can also provide rear-wheel drive with a longitudinal engine. Provide new energy electric drive solutions for mid-to-high-end passenger vehicles on the platform.

If the vehicle layout space permits, the TM4 MOTIVETM motor and inverter can also be operated in series to meet the demand for vehicles with higher body weight. According to Dana’s official information, the TM4 MOTIVETM motor and inverter can be used up to level 2 commercial vehicles, that is, the capacity of light trucks and above.

The integrated design provides a platform-based electric drive solution for Dana’s electric drive technology. In the future, such an electric drive system will also become the key to helping global auto companies move towards new energy.