At the Shanghai International Auto Show in April this year, North American auto parts manufacturer Dana officially released the enhanced TM4 MOTIVETM motor and inverter for the light vehicle market. This also means that Dana, which once occupied an important position in the automobile market and the aftermarket with traditional axles, has officially entered the era of new energy. It has realized the transformation from a traditional auto parts company to a new energy industry.

The auto industry is often like this. As the cornerstone of the entire industry pyramid, the parts industry is the cornerstone to promote the transformation of the entire industry. With the transformation of Dana at the motor drive level, Dana also has the ability to provide a complete set of hybrid and pure electric power solutions to auto companies. For the traditional automobile industry, this is undoubtedly a major benefit at the level of new energy.

Therefore, in the following text, we might as well talk about the enhanced TM4 MOTIVETM motor and inverter released at this year’s Shanghai International Auto Show.

Dana’s motor drive solutions for light vehicles began in the second half of last year. At that time, Dana established a joint venture partnership with Hydro-Québec. According to the agreement, Dana became the largest shareholder of TM4 under Hydro-Québec. And this TM4 company was previously an enterprise with strong technical advantages in electric motors, generators, power electronic equipment and control systems in the transportation market.

After Dena takes a stake, TM4’s core technologies of permanent magnet motors, thermal management systems, coil windings, motors and inverter control algorithms will be used by Dana. On the basis of the previous traditional drive axle, Dana has completed the mechanical structure design of the electric drive axle. In this way, the integration of TM4’s motor series with Dana’s electric drive axle and Spicer gearbox is the main work done by Dana. Therefore, Dana also has the ability to provide a three-in-one turnkey solution for new energy drives including electric motors, inverter algorithms, and mechanical drive axles for OEMs.

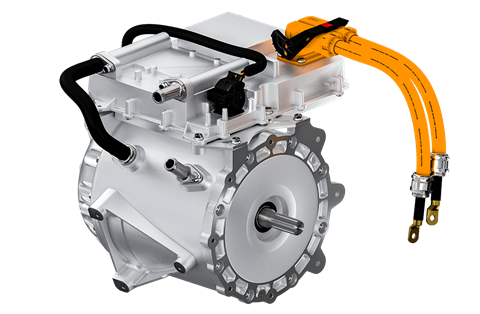

From a structural point of view, the TM4 MOTIVETM motor and inverter have high space compatibility, which makes this system more layout-friendly for small cars. In terms of size, the integrated Dana inverter is 33% smaller than the previous generation of products. The weight of the whole set is 50 kg. It can be expanded to a maximum rated power output of 150 kW and 11,000 rpm score level.

For the current mainstream passenger cars, the combination of this electric drive system, whether it is a hybrid or a pure electric drive, the output level of such an electric drive axle can already meet the needs of the market. At the same time, the optimization of space also prevents the inverter from being the main shortcoming of occupying the space of the electric vehicle cabin in the future, and realizes the ability to truly release the hard point structure of the electric vehicle platform.

Compared with traditional internal combustion engine-powered models, due to the change in power layout from the engine to the electric motor, the requirements for the cabin of pure electric vehicles will be greatly reduced in theory, and the requirements for the longitudinal space of the floor will be increased. This makes the layout of the pure electric vehicle platform different from that of traditional internal combustion engine powered models. And the interconnection between the difference on this platform and the era of intelligence will form a brand-new vehicle layout structure-a space design dominated by scene-based function realization.

However, under the current technical conditions, the size of the inverter is too large, so that the utilization rate of the cabin of the pure electric vehicle cannot be greatly improved, and it has become a restrictive factor. Therefore, from this point of view, Dana’s TM4 MOTIVETM motor and inverter have a certain degree of progress in improving the compatibility of space.

The weight of the whole set of 50 kg will also greatly change the distribution of the center of gravity of the new energy vehicle, reduce the compliance of the system with the front axle or rear axle, and then realize the full liberalization of the vehicle layout and performance settings. To give a simple example, the reduction in the weight of the front axle will greatly weaken the possibility of pushing the head of the vehicle under extreme conditions.

The friendliness of the TM4 MOTIVETM motor and inverter to the space layout and counterweight level of the vehicle also enables Dana to provide diversified solutions for OEMs.

It is reported that the new energy electric drive axle system composed of TM4 MOTIVETM motor and inverter can independently provide new energy solutions for small passenger cars with a front-wheel drive platform with a transverse engine, and can also provide rear-wheel drive with a longitudinal engine. Provide new energy electric drive solutions for mid-to-high-end passenger vehicles on the platform. Of course, if the vehicle layout space permits, the TM4 MOTIVETM motor and inverter can also be operated in series to meet the demand for vehicles with higher body weight. According to Dana’s official information, the TM4 MOTIVETM motor and inverter can be used up to level 2 commercial vehicles, that is, the capacity of light trucks and above.

The integrated design provides more possibilities for Dana’s electric drive technology. In a sense, the integrated design of TM4 MOTIVETM motor and inverter provides a platform solution for OEMs. According to Dana’s plan, the current electric drive architecture with TM4 motor as the main body will be put into production in China in 2020. This also means that this technology will serve domestic local brand enterprises and joint ventures with higher cost performance. Obviously, in the near future, this advanced electric drive technology will appear in the new energy vehicle market.