From the first car stumbled on the road 134 years ago, to now the whole car has become an integral part of our daily life. Over the past hundred years, the automobile industry has been accompanied by the progress of production technology and the global industrial industry. The establishment of a modernized production system has formed a huge industrial chain. In this industrial chain, the functions of automobile enterprises in the fields of production and R&D have been gradually refined. The era when a factory could produce a car from scratch is gone forever. The development of automobile companies, as well as the progress of the automobile industry, has also begun to shift more toward the supplier level that develops and masters core technologies in various fields.

In 2018, China’s automobile consumer market ushered in the first decline in nearly three decades. This downward trend not only did not stop in 2019, but also expanded the decline. The outbreak of the new crown epidemic that began in 2020 will make the global auto industry even worse. Coupled with the industrial changes surrounding new energy and intelligentization within the auto industry in recent years, the living environment of many auto companies has suddenly become harsh.

Therefore, survival has become a key word for major car companies around the world.

We don’t spend too much time on marketing matters, because the premise of all marketing activities is to build on a good product foundation. Therefore, in the following text, we will talk about the survival of automobile companies in the era of electrification from the perspective of the internal transformation of the automobile industry.

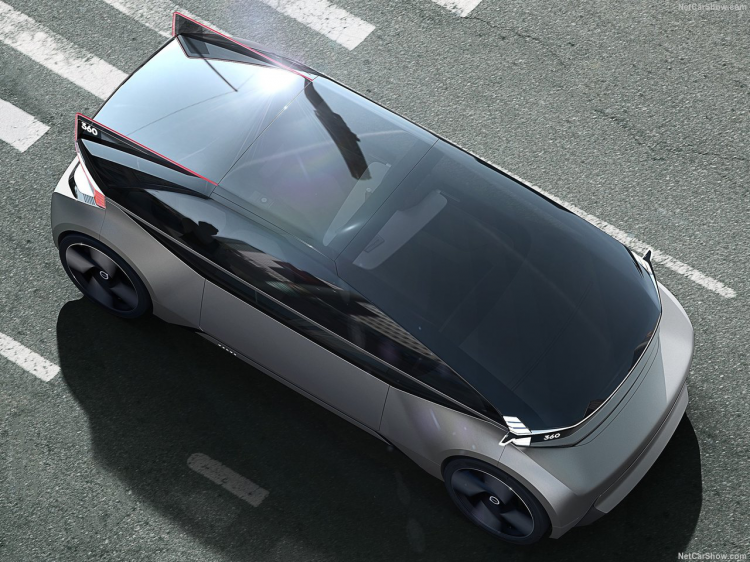

As the two keywords leading the development of the future automobile industry, new energy and intelligence will eventually be included in the field of electrification, but the emphasis of the two is different. A complete era of electrified vehicles will inevitably be an era of intelligent transportation beyond our basic understanding.

In the era of electrification, there are only two issues facing auto companies: where does the core technology of electrification come from, and how to achieve low-cost industrialization of the core technology.

After the automobile industry has experienced the subdivision of the industrial chain, most of the core technologies have been transformed into black box components, that is, automobile companies only need to provide one input and output port, and the parts suppliers will provide them with a complete set of components. Turnkey projects. Such a pattern has ushered in the rapid development of the entire industry and a substantial reduction in production costs.

So it is obvious that in the era of electrification, the core technology of automobile companies still depends on parts suppliers, and parts suppliers also need to rely on the terminal sales of automobile companies to maximize profits. Therefore, the relationship between the two is symbiotic, so we can also see such a situation. When an automobile company is put into production, the supporting parts industry will also follow.

In the era of traditional power, as a century-old shop in the drive field, Dana has gained a large number of customers in the traditional model market, and has become an important force and benchmark for the development of the automotive drive field. Dana has also established a comprehensive production base for transmission systems and thermal management systems in the domestic market, realizing localized development. This industry status is also the key to Dana’s ability to empower auto companies in the era of electrification.

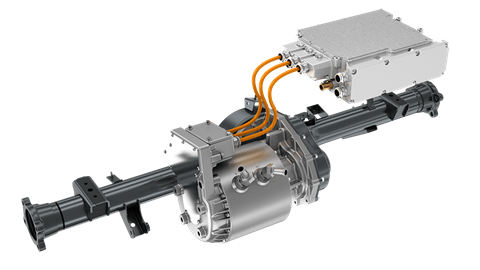

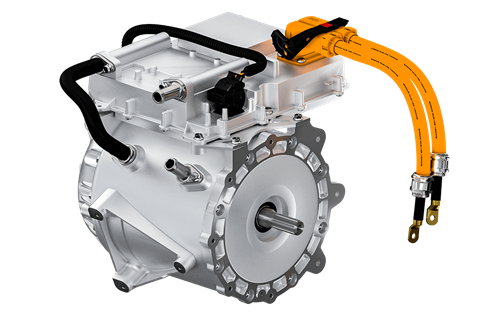

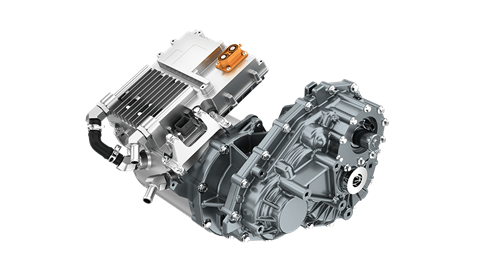

The power structure of new energy vehicles consists of three parts: electric drive system, battery pack and power management system, and Dana’s biggest advantage in this is the electric drive system. Of course, we can also regard this as the electrification transformation of Dana’s traditional advantages. A few years ago, Dana officially launched the electric gearbox as the main reduction mechanism of pure electric vehicles, and on this basis, it developed a series of products with multiple torques and multiple sizes suitable for passenger vehicles. At the same time, it has also realized a variety of product sequences including coaxial and parallel shaft motor drive methods, as well as single-speed, two-speed and four-speed.

The diversified product series enables Dana’s electric gearbox mechanism to better correspond to the plug-in hybrid and pure electric vehicles of automobile companies. The corresponding platforms also include traditional internal combustion engine powered vehicle platforms and brand-new Pure electric platform.

On this basis, Dana has integrated with the electric drive axle by acquiring the core technology of TM4’s permanent magnet motor, thermal management system, coil winding, motor and inverter control algorithm. In this way, the electrification era solutions that Dana can provide for automobile companies have become a complete set of solutions covering electric drive systems, engineering design and manufacturing. This is currently the only supplier group in the industry that can provide turnkey projects of new energy power drive systems for auto companies.

At present, Dana’s TM4 MOTIVE motor and inverter have been officially put into production in China, and the new products were officially released at the Shanghai International Auto Show last year. This series of products can be used independently as the front or rear drive of small passenger cars, or Can be configured to run in tandem. It can also be seamlessly integrated with Dana’s Spicer transmission and e-axle. This will also provide convenient solutions for domestic auto companies.

The production system previously deployed by Dana in China also provides convenience for low-cost large-scale production. The production bases in Changzhou, Yancheng and other places, relying on the Yangtze River Delta, radiate the whole country. It can be said that Dana’s electrification process has realized a chain solution from product to production, which will also become an important support for car companies to achieve transformation in the era of electrification.